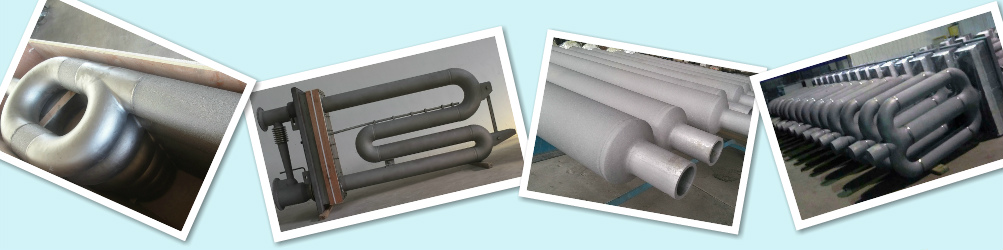

Glass roll for float glass anneal kiln

Product Description:

Glass roll in float glass anneal kiln:

1. Material: Cr25Ni20, Cr18Ni9, Cr20Ni10 or customized material.

2. Process: centrifugal cast roll body, forge shaft, welding together.

3. Specification: OD160mm, OD305mm, OD330mm, OD363mm, OD365mm or according to drawing and requirement.

4. Application: float glass anneal kiln, glass product production line parts

5. Material and Test Standard: ASME,DIN,GB or according to drawing and requirement

6. Equipment: Electric arc furnace, Intermediate frequency induction furnace, Imported Direct Reading Spectrometer, Electric Universal Testing Machine, Eddy current inspection instrument, Argon arc welding machine, Lathes, milling machines, drill presses, Boring machines,CNC grinding machines,etc.

7.Advantage: We have first rate production line, the most professional staff, and the advanced equipment and inspection method for casting. We will offer you super quality, pretty competitive price and strict delivery time.

1. Material: Cr25Ni20, Cr18Ni9, Cr20Ni10 or customized material.

2. Process: centrifugal cast roll body, forge shaft, welding together.

3. Specification: OD160mm, OD305mm, OD330mm, OD363mm, OD365mm or according to drawing and requirement.

4. Application: float glass anneal kiln, glass product production line parts

5. Material and Test Standard: ASME,DIN,GB or according to drawing and requirement

6. Equipment: Electric arc furnace, Intermediate frequency induction furnace, Imported Direct Reading Spectrometer, Electric Universal Testing Machine, Eddy current inspection instrument, Argon arc welding machine, Lathes, milling machines, drill presses, Boring machines,CNC grinding machines,etc.

7.Advantage: We have first rate production line, the most professional staff, and the advanced equipment and inspection method for casting. We will offer you super quality, pretty competitive price and strict delivery time.

Copyright © YANTAI CHONGXIN MACHINERY CO.,LTD. All right reserved